Swiss startup develops world’s first machine to produce individually personalised human tissue with potentially life-saving and life-changing outcomes.

CUTISS develops world’s first machine to produce personalised human tissue

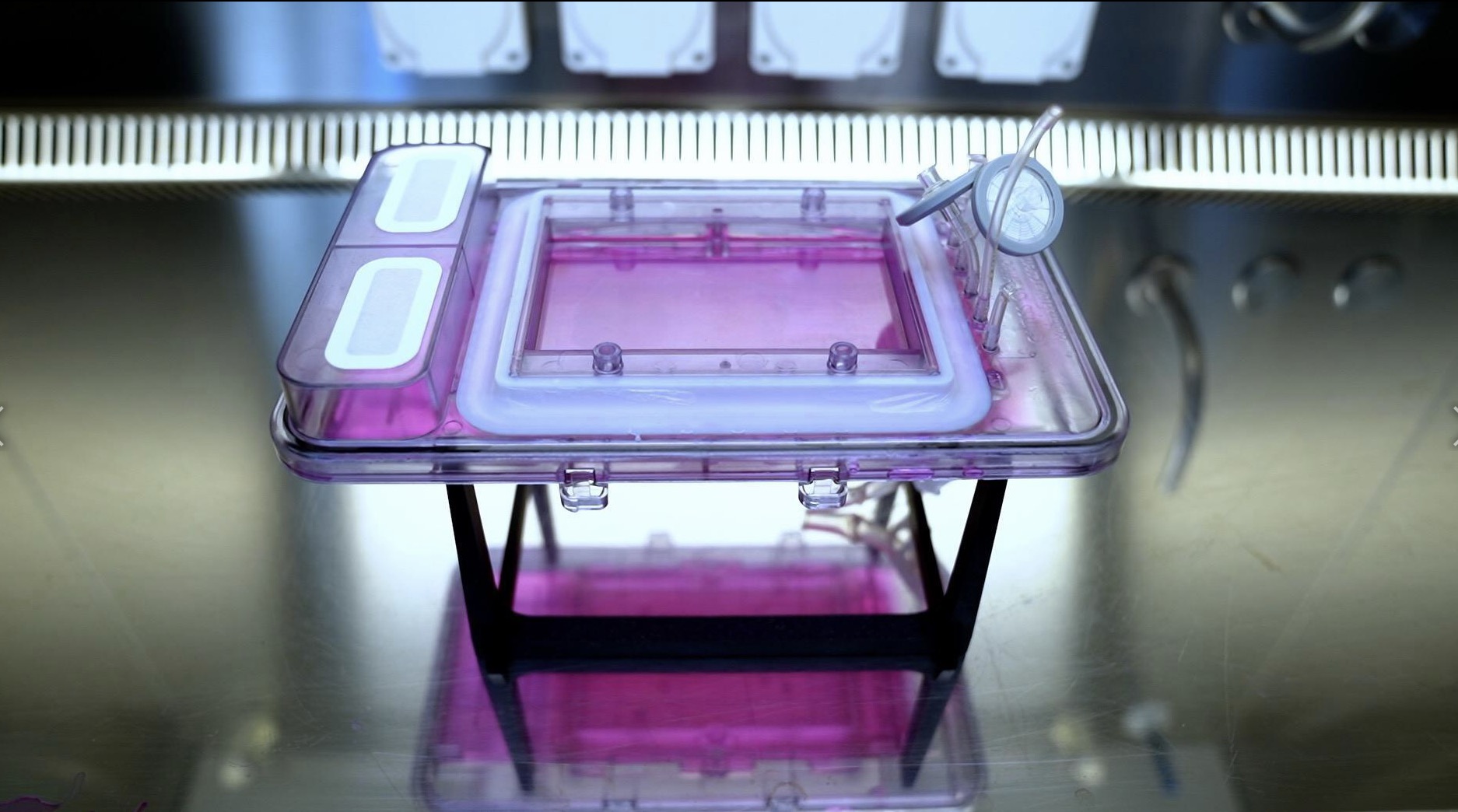

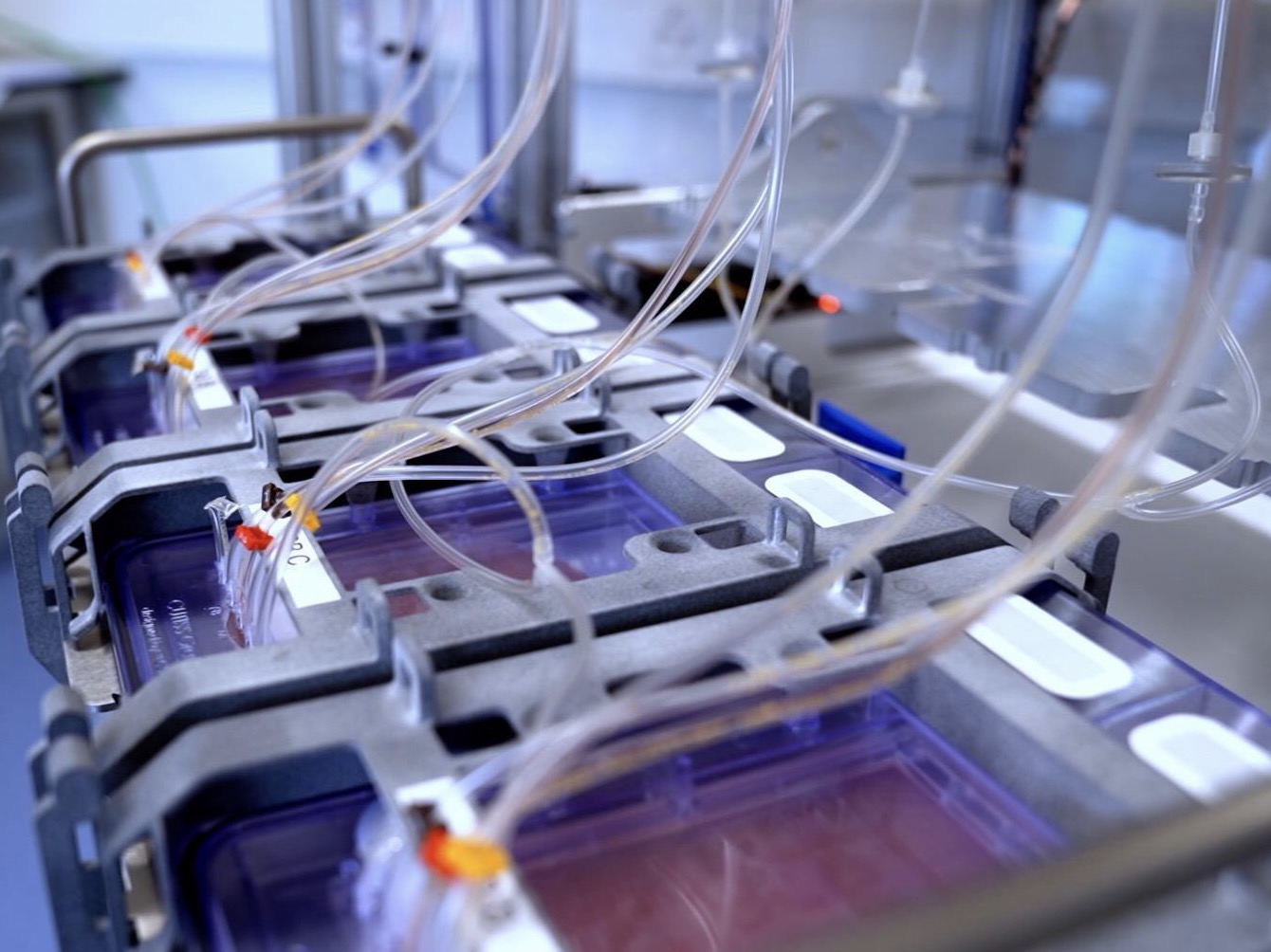

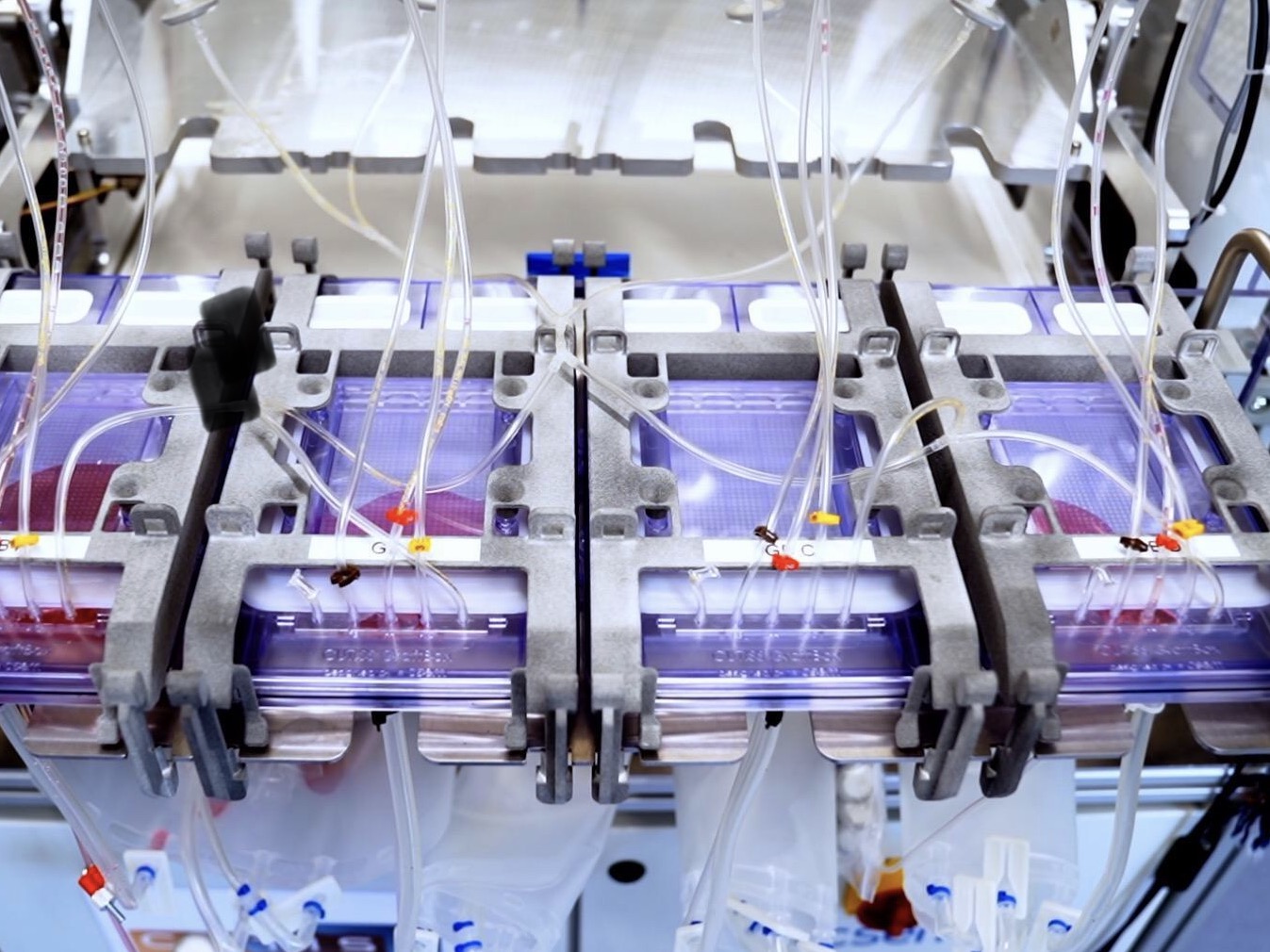

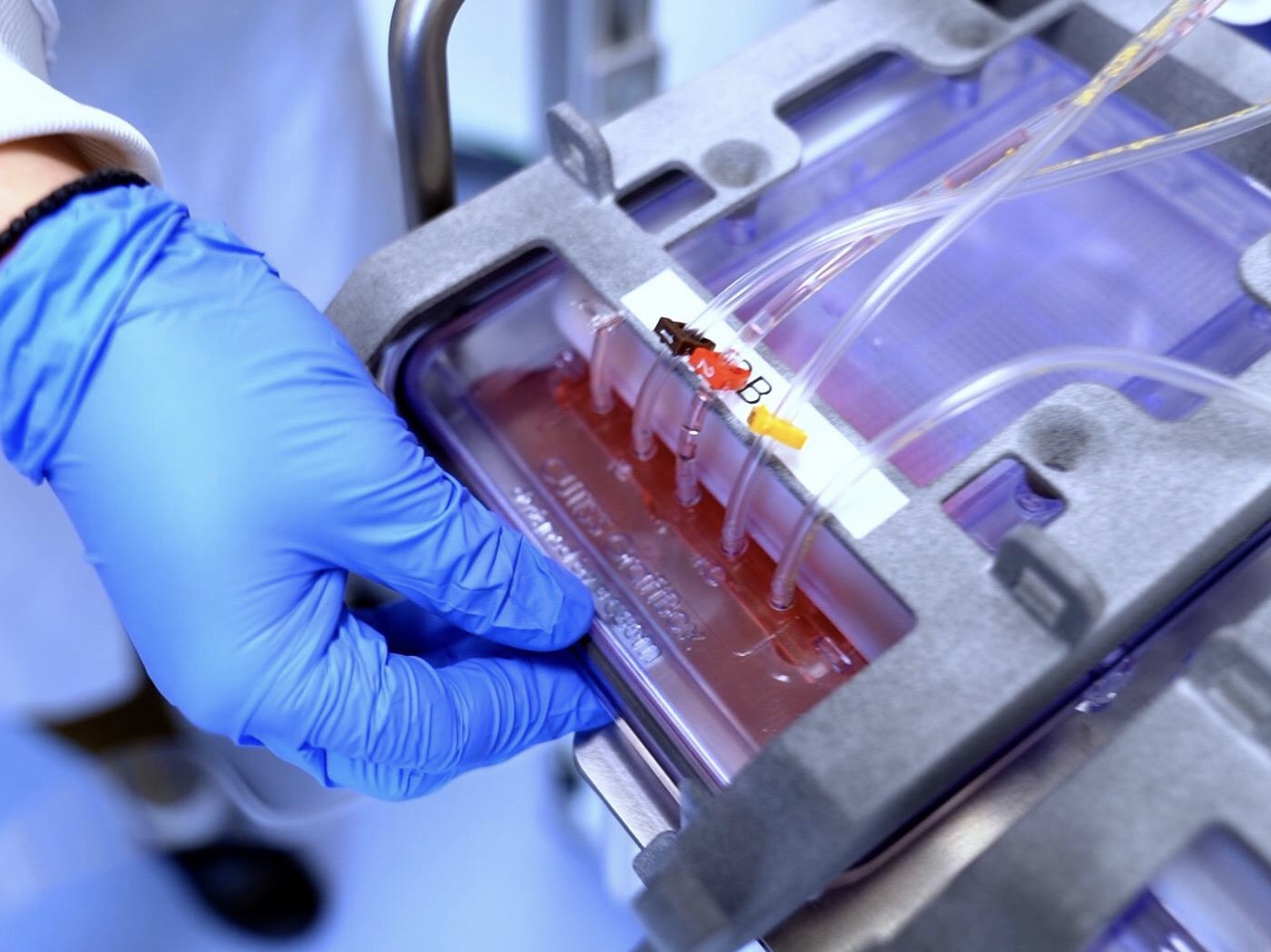

Last month, CUTISS AG, a Swiss clinical-stage life sciences company focused on skin regenerative medicine and tissue engineering, unveiled the world’s first automated machine to produce customised skin tissue grafts for adults and children with severe skin injuries, such as deep burns. Developed in collaboration with the leading Swiss research center CSEM, the denovoCast machine demonstrates the feasibility of automating the bio-engineered skin manufacturing process, and seeks to revolutionise the current available treatments for severe skin defects.

Significant need for patients with severe burns

When patients suffer from disastrous large and deep burns, the ability to quickly, affordably and consistently provide large quantities of skin grafts is essential. Survival of major burns is closely related to how fast definitive wound closure is achieved.

Speeding and scaling up the culturing process of bio- engineered, personalised skin grafts can be a game changer and crucial for saving more lives of patients with major burns, sparing patient healthy skin donor sites. Annually, 11 million patients suffer from severe burns and require skin surgery to restore skin function.

The EU and US markets for severe burns is estimated to be over $2 billion and for burn scar reconstruction is estimated over $5 billion. The current standard of care – autografting – is often scarce due to donor site shortages, produces skin that is too thin and results in permanent painful, debilitating, disfiguring scars that frequently require follow up corrective surgeries.

Source: CUTISS

denovoSkin aiming to transform skin surgery

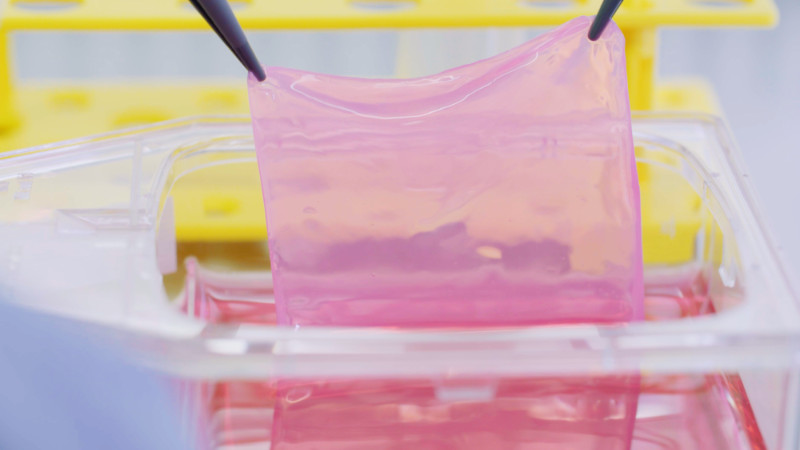

The denovoCast machine produces a particular type of skin tissue called denovoSkin, a bio-engineered and personalised dermo-epidermal skin graft developed by CUTISS. It is an innovative process involving the growth of new skin using the body’s own tissue as the template.

The denovoSkin, which is in Phase IIb clinical trials in the European Union and also accessible on a compassionate use basis, has unique features that promise to surpass any current medical treatment for large and deep skin injuries, with potentially life-saving and life-changing outcomes. It promises to grow with the patient, limit scarring, and drastically reduce the number of follow up corrective surgeries required, particularly in children.

Source: CUTISS

denovoCast machine greatly improves output and quality of skin tissue

The process for bio-engineering the denovoSkin has so far been manual, lengthy, and requiring a costly clean room, and highly trained personnel. The denovoCast machine automates tissue formation in a fully closed process, requiring no manual intervention. It ensures consistent reproducible quality, enables the simultaneous cultivation of multiple skin grafts, and is expected to reduce production times by more than 30%.

The operational denovoCast machine will now undergo research-grade testing at CUTISS to demonstrate its effectiveness and efficiency in research and clinical settings according to (Good Manufacturing Practice) GMP rules.

Source: CUTISS

HOW SAVING THE PLANET COULD ACTUALLY MAKE YOU LIVE A LOT LONGER

A recent study shows how millions of lives could be saved annually by 2040 if countries raise their climate ambitions to meet the Paris Agreement targets. Learn more.